Direct Buried

Click image to enlarge.

To download a printable file, click PDF Download >

Details

FBC RTA Direct Buried

Catalog Pages with 2023 FBC Wind Speed Map

PDF Download >

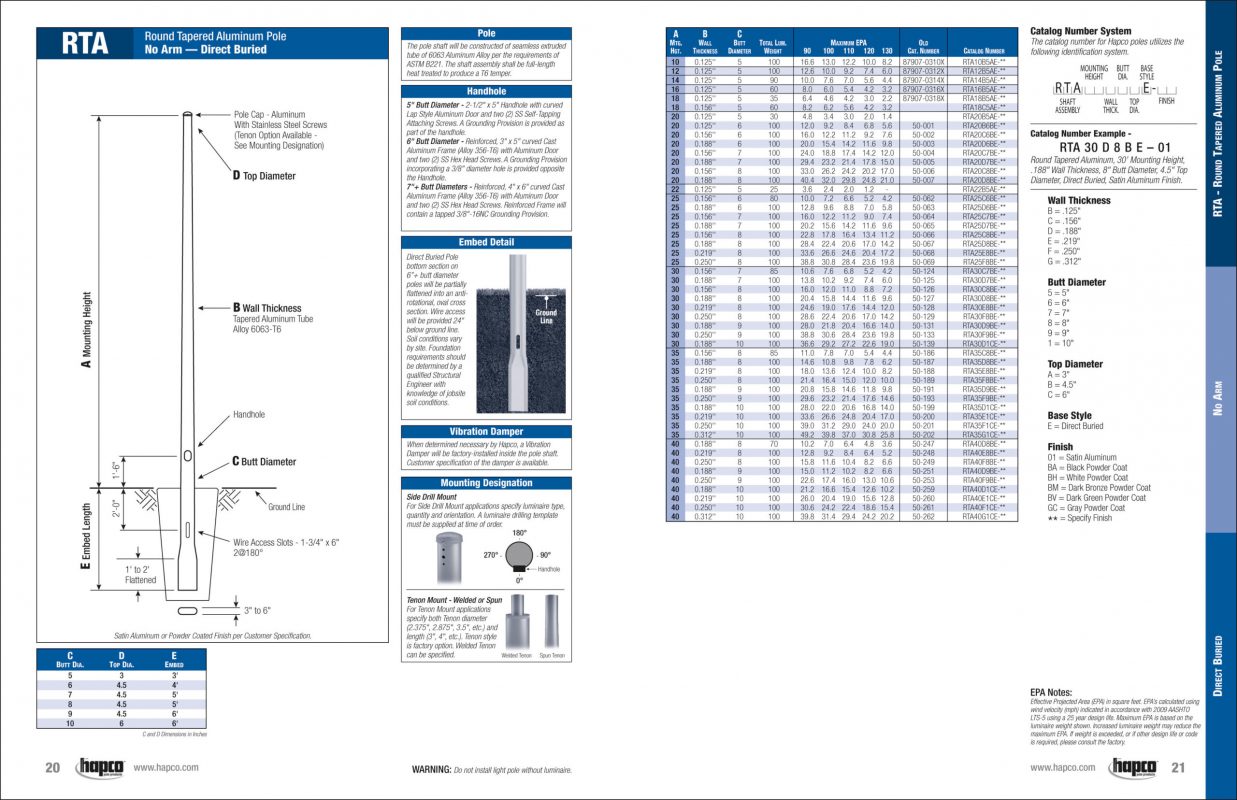

Pole

The pole shaft will be constructed of seamless extruded tube of 6063 Aluminum Alloy per the requirements of ASTM B221. The shaft assembly shall be full-length heat treated after base weld to produce a T6 temper.

Handhole

5″ Butt Diameter – 2-1/2″ x 5″ Handhole with curved Lap Style Aluminum Door and two (2) SS Self-Tapping Attaching Screws. A Grounding Provision is provided as part of the handhole.

6″ Butt Diameter – Reinforced, 3″ x 5″ curved Cast Aluminum Frame (Alloy 356-T6) with Aluminum Door and two (2) SS Hex Head Screws. A Grounding Provision incorporating a 3/8″ diameter hole is provided opposite the Handhole.

7″+ Butt Diameters – Reinforced, 4″ x 6″ curved Cast Aluminum Frame (Alloy 356-T6) with Aluminum Door and two (2) SS Hex Head Screws. Reinforced Frame will contain a tapped 3/8″-16NC Grounding Provision.

Embed Detail

Direct Buried Pole bottom section on 6″+ butt diameter poles will be partially flattened into an anti-rotational, oval cross section. Wire access will be provided 24″ below ground line. Soil conditions vary by site. Foundation requirements should be determined by a qualified Structural Engineer with knowledge of jobsite soil conditions.

Vibration Damper

When determined necessary by Hapco, a Vibration Damper will be factory-installed inside the pole shaft. Customer specification of the damper is available.

Vibration Dampers

Read More >

Mounting Designation

Side Drill Mount

For Side Drill Mount applications specify luminaire type, quantity and orientation. A luminaire drilling template must be supplied at time of order.

Tenon Mount – Welded or Spun

For Tenon Mount applications specify both Tenon diameter (2.375″, 2.875″, 3.5″, etc.) and length (3″, 4″, etc.). Tenon style is factory option. Welded Tenon can be specified.

Satin Aluminum Finish

Pole surface will contain a uniform Brushed Aluminum natural finish. Finish to be achieved utilizing specially formulated abrasives in a multi-pass, rotary sanding operation.

Powder Coat Finish

Coating material will be a thermosetting polyester AAMA 2604 Super Durable powder electrostatically applied, oven cured and bonded in a closed loop, automated system. Minimum thickness of finish will be two (2) mils. Hapco’s Powder Coat Finish Warranty on aluminum poles is five (5) years.

Finish Options

Read More >

Pole Shaft Warranty

Hapco warrants its aluminum pole assemblies for their lifetime to be free of defects in material and workmanship.

Hapco Lifetime Pole Assembly Warranty

Read More >

Specification Drawings – RTA No Arm Direct Buried

Click on the Product No. to download interactive PDF specification drawing.

| Pole Height | Product No. | Butt Dia | Wall Thickness | Old Product No. |

|---|---|---|---|---|

| 10′ | RTA10B5AE-** | 5″ | 0.125″ | 87907-0310X |

| 12′ | RTA12B5AE-** | 5″ | 0.125″ | 87907-0312X |

| 14′ | RTA14B5AE-** | 5″ | 0.125″ | 87907-0314X |

| 16′ | RTA16B5AE-** | 5″ | 0.125″ | 87907-0316X |

| 18′ | RTA18B5AE-** | 5″ | 0.125″ | 87907-0318X |

| RTA18C5AE-** | 5″ | 0.156″ | ||

| 20′ | RTA20B5AE-** | 5″ | 0.125″ | |

| RTA20B6BE-** | 6″ | 0.125″ | 50-001 | |

| RTA20C6BE-** | 6″ | 0.156″ | 50-002 | |

| RTA20D6BE-** | 6″ | 0.188″ | 50-003 | |

| RTA20C7BE-** | 7″ | 0.156″ | 50-004 | |

| RTA20D7BE-** | 7″ | 0.188″ | 50-005 | |

| RTA20C8BE-** | 8″ | 0.156″ | 50-006 | |

| RTA20D8BE-** | 8″ | 0.188″ | 50-007 | |

| 22′ | RTA22B5AE-** | 5″ | 0.125″ | |

| 25′ | RTA25C6BE-** | 6″ | 0.156″ | 50-062 |

| RTA25D6BE-** | 6″ | 0.188″ | 50-063 | |

| RTA25C7BE-** | 7″ | 0.156″ | 50-064 | |

| RTA25D7BE-** | 7″ | 0.188″ | 50-065 | |

| RTA25C8BE-** | 8″ | 0.156″ | 50-066 | |

| RTA25D8BE-** | 8″ | 0.188″ | 50-067 | |

| RTA25E8BE-** | 8″ | 0.219″ | 50-068 | |

| RTA25F8BE-** | 8″ | 0.250″ | 50-069 | |

| 30′ | RTA30C7BE-** | 7″ | 0.156″ | 50-124 |

| RTA30D7BE-** | 7″ | 0.188″ | 50-125 | |

| RTA30C8BE-** | 8″ | 0.156″ | 50-126 | |

| RTA30D8BE-** | 8″ | 0.188″ | 50-127 | |

| RTA30E8BE-** | 8″ | 0.219″ | 50-128 | |

| RTA30F8BE-** | 8″ | 0.250″ | 50-129 | |

| RTA30D9BE-** | 9″ | 0.188″ | 50-131 | |

| RTA30F9BE-** | 9″ | 0.250″ | 50-133 | |

| RTA30D1CE-** | 10″ | 0.188″ | 50-139 | |

| 35′ | RTA35C8BE-** | 8″ | 0.156″ | 50-186 |

| RTA35D8BE-** | 8″ | 0.188″ | 50-187 | |

| RTA35E8BE-** | 8″ | 0.219″ | 50-188 | |

| RTA35F8BE-** | 8″ | 0.250″ | 50-189 | |

| RTA35D9BE-** | 9″ | 0.188″ | 50-191 | |

| RTA35F9BE-** | 9″ | 0.250″ | 50-193 | |

| RTA35D1CE-** | 10″ | 0.188″ | 50-199 | |

| RTA35E1CE-** | 10″ | 0.219″ | 50-200 | |

| RTA35F1CE-** | 10″ | 0.250″ | 50-201 | |

| RTA35G1CE-** | 10″ | 0.312″ | 50-202 | |

| 40′ | RTA40D8BE-** | 8″ | 0.188″ | 50-247 |

| RTA40E8BE-** | 8″ | 0.219″ | 50-248 | |

| RTA40F8BE-** | 8″ | 0.250″ | 50-249 | |

| RTA40D9BE-** | 9″ | 0.188″ | 50-251 | |

| RTA40F9BE-** | 9″ | 0.250″ | 50-253 | |

| RTA40D1CE-** | 10″ | 0.188″ | 50-259 | |

| RTA40E1CE-** | 10″ | 0.219″ | 50-260 | |

| RTA40F1CE-** | 10″ | 0.250″ | 50-261 | |

| RTA40G1CE-** | 10″ | 0.312″ | 50-262 |